Closed Loop Supply Chain Management

The art of designing a sustainable supply chain

India is a rapidly developing economy with a population of over 1.3 billion people. The country is facing significant environmental challenges, including air pollution, water scarcity, and waste management. In recent years, there has been increasing interest in the concept of a closed loop supply chain in India, which aims to reduce waste and promote sustainable consumption. One key aspect of closed loop supply chains is the use of returnable packaging, which can reduce costs and environmental impact. In this blog post, we will explore the concept of closed loop supply chains with an emphasis on returnable packaging in the Indian context.

What is a Closed Loop Supply Chain?

A closed loop supply chain is a system that aims to reduce waste and promote sustainability by keeping resources in use for as long as possible. In a traditional linear supply chain, resources are extracted, used to produce goods, and then disposed of as waste. In a closed loop supply chain, resources are instead reused, recycled, or repurposed to create a closed loop system.

The closed loop supply chain model can be applied to many industries, including manufacturing, retail, and logistics. In a closed loop supply chain, waste is minimized, and resources are used more efficiently, reducing costs and environmental impact.

The Importance of Returnable Packaging in Closed Loop Supply Chains

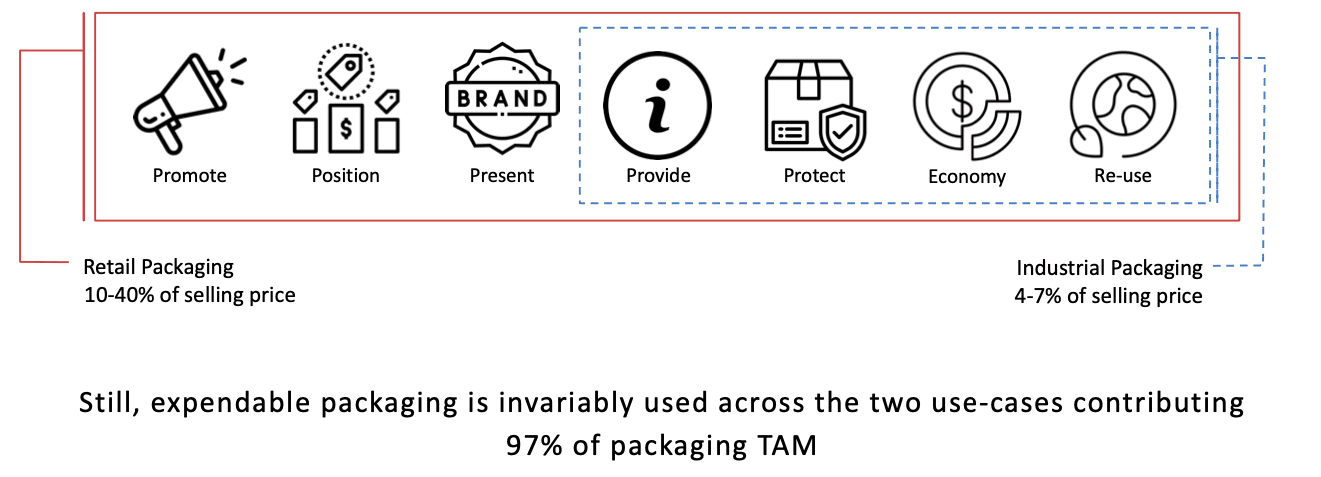

Returnable packaging is an important element of a closed loop supply chain. Returnable packaging refers to packaging materials that are designed to be reused multiple times. This can include containers, pallets, and crates, among others. Returnable packaging is durable and can withstand repeated use, reducing the need for single-use packaging materials.

Returnable packaging can have significant benefits for businesses. By using returnable packaging, businesses can reduce costs associated with purchasing and disposing of single-use packaging materials. Additionally, returnable packaging can improve supply chain efficiency by reducing the need for frequent deliveries and pickups of packaging materials.

Returnable packaging can also have significant environmental benefits. By reducing the need for single-use packaging materials, returnable packaging can reduce waste and conserve natural resources. Additionally, returnable packaging can reduce greenhouse gas emissions associated with the production and transportation of single-use packaging materials.

Examples of Closed Loop Supply Chains with Returnable Packaging in India

1. Coca-Cola India

Coca-Cola India has been a leader in sustainable packaging in India. In 2019, the company announced that it had successfully achieved its goal of using 50% recycled content in its plastic bottles in India. Additionally, the company has been exploring the use of returnable packaging as a way to reduce waste and lower costs.

In 2018, Coca-Cola India launched a pilot program in Chennai called “Project Unnati” which involved using returnable glass bottles for its beverages. The bottles were collected and sent back to the company to be washed and refilled, creating a closed loop system. The program was successful in reducing waste and promoting sustainable consumption habits among customers.

2. Amul

Amul, the Indian dairy cooperative, has also embraced closed loop supply chains and returnable packaging. In 2019, the company announced that it would use returnable glass bottles for its milk products, reducing the need for single-use plastic packaging. The bottles are collected and sent back to the company to be washed and refilled, creating a closed loop system. Amul has also implemented similar programs for its ice cream products, promoting sustainable consumption and reducing waste.

3. Flipkart

Flipkart, the Indian e-commerce company, has also implemented closed loop supply chains and returnable packaging. In 2019, the company announced that it would use returnable plastic packaging for its deliveries, reducing the need for single-use packaging materials. The packaging is designed to be durable and withstand repeated use, reducing waste and lowering costs. Additionally, Flipkart has implemented a program to collect and recycle e-waste generated by its customers, further promoting a closed loop system.

Challenges and Opportunities for Closed Loop Supply Chains with Returnable Packaging in India

Implementing closed loop supply chains with returnable packaging in India can be challenging due to a variety of factors. These can include logistical challenges associated with collecting and transporting packaging materials, as well as cultural barriers to sustainable consumption.

However, there are also significant opportunities for closed loop supply chains with returnable packaging in India. As the examples above show, many companies are already implementing successful programs that promote sustainable consumption and reduce waste. Additionally, the Indian government has recognized the importance of sustainability and has implemented policies to promote sustainable practices, including the “Swachh Bharat Abhiyan” (Clean India Mission).

In conclusion, closed loop supply chains with returnable packaging have significant potential to promote sustainable consumption and reduce waste in India. By keeping resources in use for as long as possible, businesses can reduce costs and environmental impact, while promoting sustainable consumption habits among customers. While there are challenges associated with implementing closed loop supply chains in India, there are also significant opportunities for businesses to make a positive impact on the environment and society.

Yantra Packs Insights: Closed loop supply chain is as much about sustainability as it is about cost optimisation

Closed loop supply chain is a sustainable business model that promotes the use of materials and resources in a way that minimizes waste and pollution. It entails the collection, refurbishment, and reuse of products and materials that would have otherwise been disposed of as waste. This approach has gained popularity in recent years due to its positive impact on the environment, but it is also budget-friendly for businesses.

Closed loop supply chain helps organizations reduce their operating costs by eliminating waste and reducing the amount of raw materials required to produce new products. It allows companies to recover the value of their products and materials, which would have otherwise been lost in the disposal process. This results in significant savings for businesses and reduces the need for new investments in raw materials.

The closed loop supply chain also promotes efficient resource utilization and reduces the amount of energy required to produce new products. This leads to lower carbon emissions and helps companies meet their sustainability goals while creating a positive impact on the environment.

Moreover, the closed loop supply chain enables businesses to develop a competitive advantage by creating a circular economy that promotes sustainability. This approach helps companies to build customer loyalty, increase brand reputation, and improve their bottom line.

If you are a user of secondary packaging in an industrial supply chain use-case, Yantra Packs can help you achieve sustainability along with optimisation of cost. Wish to know more? Contact us here.

No comment